SummaCut vinyl cutters

Since 1996, SummaCut has evolved to become the world’s most advanced performance-price leader.

The new SummaCut Series is the product from decades of Summa’s brilliant European engineering.

Numerous refinements have been made in the SummaCut Series, such as OPOS-X technology, known from our most advanced S-Class cutting plotters, is now integrated into a newly designed drag-knife cutting head.

The SummaCut Series features highly complex algorithms to compensate for any deformation of the print, using the world’s most reliable sensor technology; this makes SummaCut a winning contour cutter for any sign or print shop.

Milled from the finest materials, in a unique process that assures each roller has an exacting diameter, we then specially coat each roller to eliminate the risk of wear and oxidation that can degrade tracking over time.

Summa’s world renowned quality craftsmanship delivers cutting performance and reliability that outclasses other top-of-the-line cutters. It is no wonder the affordably priced SummaCut Series is one of the most popular vinyl cutters ever built.

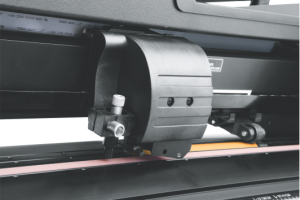

Newly designed high-speed cutting head

The new cutting head features precision accuracy for exceptionally reliable and effortless vinyl cutting.

Summacuttersare loadedwithseveralintelligentroutinesoptimisingthecuttingdata. All Summa Series use an advanced vector look-ahead technology that cuts complex imagesandletteringwithimprovedefficiency. The benefits are extensive. Cuttingtime is reduced seriously, curves are smoother and the motors are less loaded, which increases the life time of the cutting plotter.

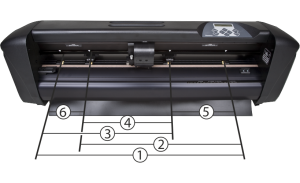

Easy-to-use control panel

that allows you to quickly and easily change settings like speed, pressure, plot mode and perform test cuts.

Multiple languages available such as English, Dutch, German and French.

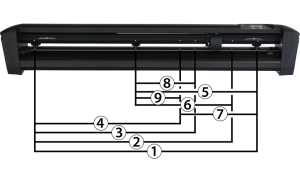

Optimized transport & tracking

Integrated media rollers and roll end flanges load your vinyl straight and keep your media on track, even cutting at top speed.

Tracking is the ability to transport the media through the machine in a repetitive way. This ability makes sure that one single job is cut within specifications within the complete guaranteed tracking length. Nevertheless, longer jobs are also accepted by the cutter.

The guaranteed tracking length also indicates the possibility of doing multiple jobs after each other (exceeding the guaranteed tracking length several times) without the need of reloading the media.

Contour cutting with OPOS X

OPOS X contour-cutting alignment means you can die-cut valuable printed vinyl graphics with complete confidence and reliability.

The automated contour alignment system OPOS stands for Optical Positioning System. The OPOS X sensor technology senses marks on a wide range of materials.

Some of our latest features include a fully automated workflow with barcode reading, enabling you to contour-cut multiple jobs without any user intervention. Another feature is while using multiple sheets with repeating graphics, the OPOS sensor will start looking for markers immediately after a new sheet is loaded.

Which SummaCut model will I need?

D60R / 60cm

D120R / 120cm

D140R / 140cm

D160R / 160cm

With an FX model you are slightly less flexible in controlling the distance from the rollers to the edge of your film: the pinch rollers can only be placed on certain fixed positions. It does allow you to cut most standard vinyl widths.

4 pinch roller positions

for 6 basic widths

D60FX / 60cm

4 pinch roller positions

for 6 basic widths

D140FX / 140cm

6 pinch roller positions

for 9 basic widths

6 pinch roller positions

for 9 basic widths

For these applications:

Explore the SummaCut brochure

Specifications

Plot Speed

Max 1130mm/s diagonal

Mechanical Precision

0,2% or 0,25mm

Plot Width

Up to 157 cm

Plot Length

Up to 50 meters

Plotter

Plot speed

Max. 1130mm/s

Plot length

Max. 50.000mm (50m)

Max. media width

D60: 7 – 66cm

D120: 12 – 127cm

D140: 18 – 142cm

D160: 18 – 164cm

Cutting range width:

D60: 60cm

D120: 120cm

D140: 135cm

D160: 157,5cm

Cutting range width (oversized mode):

D60: 63cm

D120: 123cm

D140: 138cm

D160: 160,5cm

Acceleration

Up to 3G diagonal

Knife pressure

0-400g, adjustable per 5 gram

Mechanical precision

0,2% or 0,25mm (highest value counts)

Repeating precision (guaranteed)

0.1mm 8m on rolls with max width 76cm

0.1mm 4m on rolls wider than 76cm

Connectivity

USB, RS-232 serial

Dimensions incl. stand

D60: 100 x 68 x 112cm (w x d x h)

D120: 160 x 68 x 112cm (w x d x h)

D140: 175 x 68 x 115cm (w x d x h)

D160: 198 x 68 x 115cm (w x d x h)

Power

Input voltage

110-230V, 50Hz/60Hz

Environment

Operation temperature

5°C – 40°C

Operating humidity

25% – 85%, non-condensing

Storage temperature

-40°C – 60°C

Storage humidity

10% – 90%, non-condensing

Ventilation

Free air

Evironmental compliance

CE, RoHS, WEEE

Supplies

Quality

The adhesive films are produced under the UNI EN ISO 9001-mark, which is a sign of quality and prestige, gained through the constant improvement of production processes.

The factory also has the environmental certificate UNI EN ISO 14001 to emphasize the commitment to protect our environment.

Vinyl rolls

Easy vinyl

Self-adhesive vinyl for indoor and outdoor usage, perfect for the decoration of showcases, displays, panels / plates for short-term use and exhibition stands. Shelf-life of 3 years outdoors. Glue: acrylic semi-permanent with high adhesiveness. Vinyl thickness: 80 micron. Available colors: 25 glossy, 33 matte.

Elite vinyl

Self-adhesive vinyl for the decoration of shop windows, billboards, cars, exhibitions and for all outdoor medium-lasting applications on flat surfaces. Shelf-life for outdoor use for 5 years. Metallized colors 3/4 years. Glue: eco-acrylic permanent with high adhesiveness. Vinyl thickness: 75 micron. Available colors: 59 glossy, 51 matte.

Cast vinyl

High quality adhesive cast film for the decoration of cars, ships, aircrafts, containers and signs. Pliable and flexible on bent and riveted surfaces. Wet method can be used as well. Shelf-life of 8-10 years outdoors. Metallized colors will last 5 years. Glue: acrylic, ultra permanent, extra adhesive. Vinyl thickness: 55 micron, C/967 90 microns. Available colors: 86 glossy, 2 matte and one carbon-like.

Application tape

Types

Paper, light yellow – Low adhesive: easily apply your signs with our application tape.

Length

100 meters

Widths

50mm, 100mm, 150mm, 200mm, 280mm, 300mm, 350mm, 450mm and 610mm

Software for your vinyl cutter

See all of the possibilities!

FlexiSIGN software

Design and Production from A to Z, no need for extra software.Complete package

SAi Flexi is the only all-in-one design, print and cut software.

With nearly 3 out of 4 shops using it, Flexi is the industry-standard for sign-specific design tools, RIP and print, print-and-cut, and direct vinyl cutting.

Do you want to see all of the features? See our FlexiSIGN page!

WinPlot / MacSign Cut & your own design software

Software that lets you send jobs to your cutter from your existing software.Free software!

WinPlot for Windows and MacSign Cut for Apple OS X are supplied free with your Summa cutter!With this software you can send your own design file (EPS) to your vinyl cutter.

You can easily control the number of copies, desired dimensions and all other cutter settings.

You can not change the design in WinPlot / MacSign Cut. You would need to do this using your existing design software, such as Adobe Illustrator or Corel Draw. Or use the free open source design software Inkscape.

Don’t hesitate to contact us incase you have any questions or if you would you like some advice.

EasySIGN software

Design and Production from A to Z, no need for extra software.Complete package

Create stunning signs in less time with EasySIGN® software.This full featured Designing, Plotting, Printing, Routing and Production software is used to create award winning signs all over the world.

Do you want to see all of the EasySIGN features? Have a look at our EasySIGN page!

Downloads

Meet the SummaCut!

A non-binding demonstration?

More information here!An introduction with no obligations

Our sales representative will give you a free demonstration at our office.

This allows you to get familiar with the system, the use and its benefits.

Fill in the form below and we will contact you!

Vul hieronder uw gegevens in.

Please select a valid form